Supply Chain Due Diligence Act

Supply Chain Due Diligence Act

Implementation of the Supply Chain Act (LkSG)

Implementation of the Supply Chain Act (LkSG)

– Trusted by –

Effective and economical

supplier management

The Supply Chain Act has been passed!

The Supply Chain Act has been passed!

Starting 2023, supply chains from raw material extraction to delivery to end customers must be resilient to violations of human and environmental rights. For affected companies that need to manage such a complex task effectively, but also as economically as possible, there is no way around a thematically oriented, IT-supported compliance solution.

the supply chain act

the supply chain act

The Supply Chain Due Diligence Act (LkSG) creates clarity!

The Supply Chain Due Diligence Act (LkSG) creates clarity!

As of July 2021, discussions on legal requirements for human rights compliance in supply chains have ended. With the adoption of the “Act on Corporate Due Diligence in Supply Chains”, the German Bundestag determines what measures larger companies will have to take to prevent violations of human rights and environmental obligations in their supply chains.

What are the points of the Supply Chain Act based on?

What are the points of the Supply Chain Act based on?

Pillars of the UN Guiding Principles on the Supply Chain Act (LkSG)

The Supply Chain Duty of Care Act aims to enforce the UN Guiding Principles on Business and Human Rights, which were adopted by the UN Human Rights Council in 2011. These principles apply to all states and all business enterprises, regardless of their size, sector, location or ownership.

The 31 Guiding Principles are intended to help prevent or eliminate human rights violations in business. They are based on three pillars, which the German Federal Ministry for Economic Cooperation and Development describes as follows:

Every state is obligated to create the political and legal framework for

companies and investments to ensure the protection of human rights and

To ensure labor standards. These include, for example, environmental oversight

and a labor inspection.

Businesses should establish due diligence procedures to ensure that their business activities do not have a negative impact on human rights or the environment. These procedures should aim to avoid, reduce, or compensate for any such impacts.

Persons whose human rights have been violated by companies must have effective

Remedy received. These include access to governmental and non-governmental

complaints offices and the possibility of taking legal action.

Germany is not alone: Regulations in other countries

Although Germany is leading the way with its national Supply Chain Act, the clear goal is still to adopt an EU-wide regulation. It is likely that the German law will serve as a blueprint for the EU.

Similar regulations are already in place in other countries, although they are not as comprehensive as the German Supply Chain Act. In France, the “Loi de vigilance” has been in force since 2017, which penalizes serious violations of fundamental rights, health, personal safety and the environment that take place in the supply chains of large companies. In the Netherlands, the “Wet Zorgplicht Kinderarbeid” obliges companies to investigate supply chains of goods and services sold in the Netherlands for possible instances of child labor.

Obwohl Deutschland mit seinem nationalen Lieferkettensorgfaltspflichten-gesetz vorangeht, ist es noch immer das klare Ziel, eine EU-weit geltende Regelung zu verabschieden. Es ist wahrscheinlich, dass das deutsche Gesetz der EU als Blaupause dienen wird.

In anderen Ländern sind bereits ähnliche Regelungen in Kraft, die allerdings nicht so umfassend wie das deutsche Lieferkettensorgfaltspflichten-gesetz sind. In Frankreich gilt seit 2017 das “Loi de vigilance”, das in den Lieferketten von Großunternehmen stattfindende schwerwiegende Verstöße gegen die Grundrechte, die Gesundheit, die Sicherheit von Personen und Umwelt ahndet. In den Niederlanden verpflichtet das „Wet Zorgplicht Kinderarbeid“ Unternehmen, Lieferketten von Waren und Dienstleistungen, die in den Niederlanden vertrieben werden, hinsichtlich möglicher Kinderarbeit zu untersuchen.

The compliance requirements of the Supply Chain Act (LkSG)

The compliance requirements of the Supply Chain Act (LKSG)

Who must deal with compliance in the supply chain?

Who must deal with compliance in the supply chain?

The requirements of the Supply Chain Act are mandatory for larger companies based in Germany.

Die Vorgaben des Lieferketten-sorgfaltspflichtengesetzes sind für größere Unternehmen mit Sitz in Deutschland verpflichtend. Konkret gilt das Lieferkettensorgfalts-pflichtengesetz ab dem 01.01.2023

- Companies based in Germany with at least 3000 workers, plus all employees of the company who are on assignment abroad, all temporary workers and employees of affiliated companies (in the case of corporate groups).

- All German branches with at least 1000 employees, starting on January 1st, 2024. The figure above decreases for everyone in the same date.

How far does the Supply Chain Act go?

How far does the Supply Chain Compliance System go?

duty law?

Why should companies with under 1000 employees pay attention to the Supply Chain Act as well?

Why should companies with less than 1000 employees also respect the Supply Chain Act?

Companies with fewer than 1,000 employees do not, legally speaking, have to deal with the Supply Chain Act (LkSG). However, it would be advisable for all partners in the supply chain to comply with human rights, labor standards and environmental requirements.

- If the company itself serves as a supplier for a larger company

- Avoidance of reputational damage

- The Supply Chain Act applies to all industries!

These rules of the Supply Chain Act apply to everyone!

These rules of the Supply Chain Act apply to everyone!

The most important rules of the Supply Chain Act

The most important rules of the Supply Chain Act

The aim of the Supply Chain Act is to prevent human rights and environmental risks, to minimise them where necessary, and to put an end to existing violations. The regulations of the Supply Chain Act basically apply to the entire supply chain;

starting with the extraction of raw materials through to delivery to the end customer.

Das Lieferkettensorgfaltspflichtengesetz hat das Ziel, menschenrechtlichen und umweltbezogenen Risiken vorzubeugen, sie gegebenenfalls zu minimieren und vorliegende Verstöße zu beenden. Die Regelungen des Lieferkettensorgfalts-pflichtengesetzes gelten grundsätzlich für die gesamte Lieferkette; angefangen bei der Gewinnung von Rohstoffen bis hin zur Lieferung an den Endkunden.

Risk analysis

Defined procedures help in the proper and quick follow-up of whistleblower tips. The coordination of the measures lies with a single person.

Risk management

A risk management system must be established to prevent adverse effects on human rights and the environment or to rectify existing breaches of duty.

Complaints procedure

The establishment of a complaints procedure is mandatory.

Documentation and reporting

Ongoing documentation and annual reporting on management and measures taken because the Supply Chain Act makes the degree of responsibility dependent on the depth of the supply chain and the related possibility of exerting influence, companies are only required to take immediate and adequate action in the case of indirect Tier 2 suppliers as soon as they become aware in a substantiated manner of a possible breach of the requirements.

The Supply Chain Act and your company

Das LieferkettenSorgfalts-pflichtengesetz und Ihr unternhemen

What does this mean for your company?

What does this mean for your company?

For companies, analyzing and monitoring supply chains involves some effort.

Risk analysis example:

As part of the risk analysis, you must first determine which

suppliers themselves and which of their activities pose a risk to human rights compliance and where environmental violations are likely to occur. Some examples of potential risks include:

- Where are occupational health and safety rights at risk?

- Where might forced or child labor be taking place?

- Are there risks in the procurement of raw materials?

- What are the environmental risks?

- Are there any risks associated with waste disposal?

- Do areas exist that are vulnerable to discrimination and unequal treatment of employees?

In addition to the processes in your own company and at your direct suppliers, you must also consider the processes at indirect suppliers if there are specific indications – this ranges from the procurement of raw materials and parts to transport and production.

Supply Chain Act? No problem!

Supply Chain Act? No problem!

IT-supported analysis and monitoring of the supply chain

bring advantages!

IT-supported analysis and monitoring of the supply chain bring benefits!

As the examples just mentioned show, supply chain analysis, management, monitoring, documentation and reporting is a very costly and complex process. Manual tasks, Excel lists, individually written mails and protocols in Word are only of limited help here. Rather, end-to-end digitization in conjunction with a workflow-supported IT solution is essential. This is the only way to achieve efficient data management and a high degree of automation.

An example from the business partner due diligence, which is part of a digital supply chain compliance solution, shows the enormous savings potential of IT-supported processes: If an employee manages and monitors the business partners manually, they are already fully occupied with the handling of 50 critical business partners. With an IT-supported business partner check with automated processes, the workload can be significantly reduced and the quality improved.

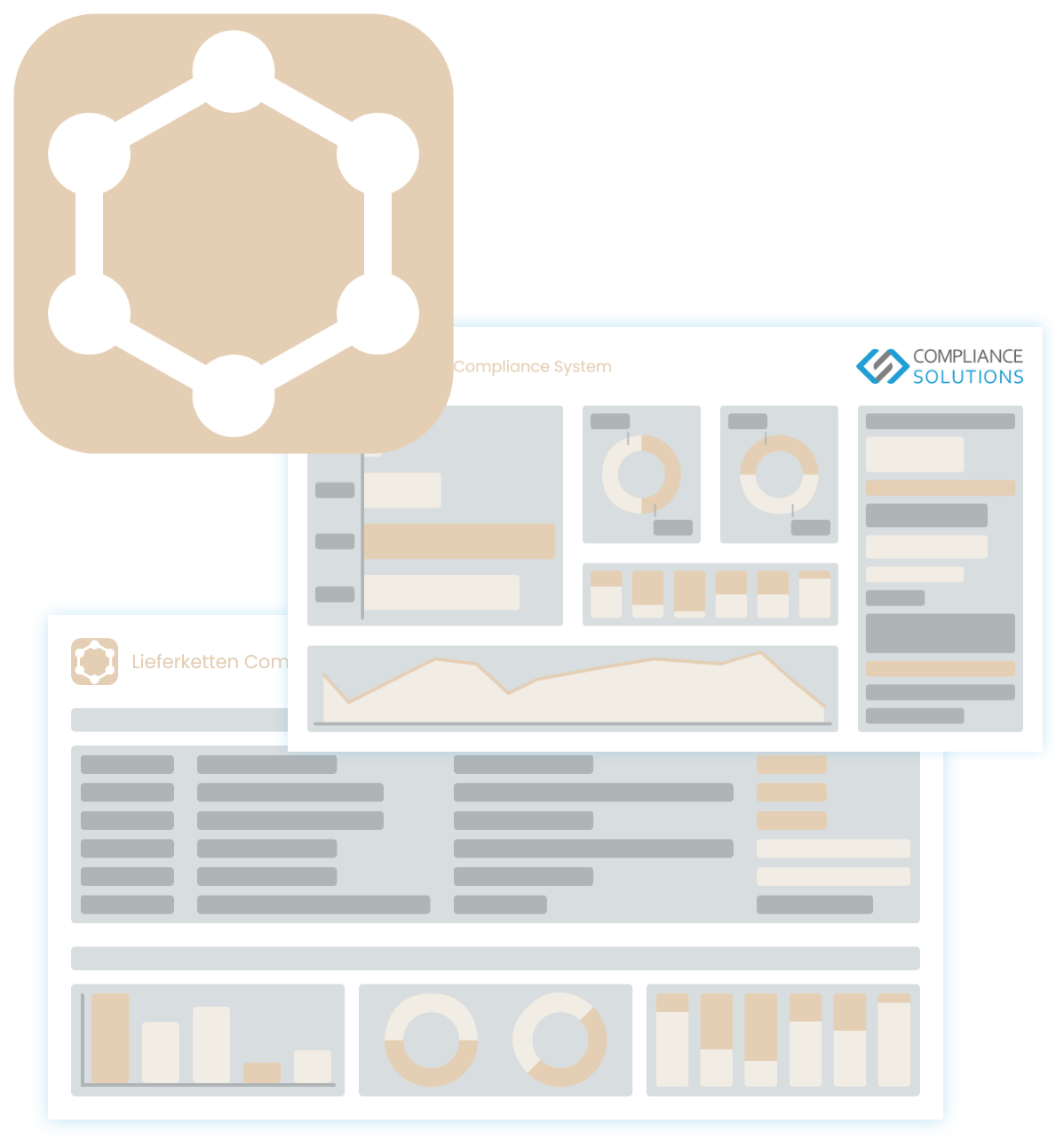

The Supply Chain Compliance System

What does the Supply Chain Compliance System offer?

What does the Supply Chain Compliance System offer?

Compliance Solutions provides the Supply Chain Compliance System, a holistic supply chain risk management solution that meets the requirements of the Supply Chain Act. The system identifies risks along the supply chains with a high degree of automation.

In doing so, it recognizes and evaluates the potential damage at an early stage so that you can initiate appropriate measures.

The Supply Chain Compliance System from Compliance Solutions guides you through the necessary steps for risk analysis and reporting in a guided process with defined roles in an audit-proof manner:

- Upfront Risk Assessment

- Detailed examination of suppliers including survey

- Sanctions list check (PEP, Black, Watch lists, Adverse media)

- Structured internet research about the suppliers

- Automated risk identification and setting of red flags

- Supplier risk assessment

- Permanent screening and monitoring to identify new risks

- Compliance audits

- BI & Reporting

Contact

Individual Advice on the Supply Chain Compliance System

Individual Advice on the Supply Chain Compliance System

Are you interested in our Supply Chain Compliance System? Please write to us, our compliance experts will be happy to advise you.